This site uses functional cookies and external scripts to improve your experience.

If you want to know more or deny consent to all or some cookies click the following link you will find our extended information on cookies and an explanation on how to disable cookies on the major browsers.

ADRENALINA PURA – NI 64′

Year: 2000

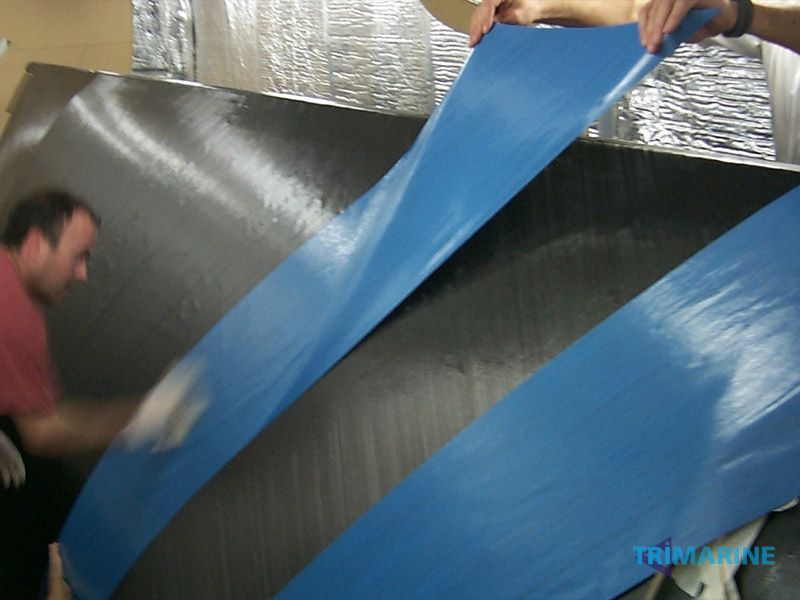

Contacted in 1998 by a client that wanted a fast and sportive boat to navigate in the Brazilian tropical waters, Trimarine has been involved from the onset in the definition of the type of vessel. On the basis of the customer’s requirements several configurations were evaluated which steered the choice towards the construction of a sports catamaran of 18-20 metres LOA. Taken this decision and examined the possible designers, the definitive choice has fallen on Nigel Irens who has designed a 64 ‘ hull with adequate inner habitability and adapted to the role of sportive cruiser. The owner, a sailing fan, had expressed desire to have the boat built nearby so he could follow its genesis in the free moments, but the impossibility to find a yard that offered sufficient guarantees for an advanced construction – Epoxy pre-impregnated carbon composite with Nomex honeycomb and Corecell (SAN) sandwich core – has forced Trimarine to decide, together with owner, to build an appropriate yard in a structure that, subsequently, would be used for the maintenance of the catamaran and other boats. The hull design and the yard construction started practically at the same time and in the summer of 1999 the construction of the female carbon moulds begins using the male plugs built in the previous months. In order to reduce the construction time it was necessary to open several parallel building fronts with the construction sequence and the supply management tightly based upon the construction process and schedule devised by Trimarine. A first group was in charge of the hulls construction, while other two groups worked in parallel in the construction of the internal structures and the complex cross arms/cockpit assembly. In addition to these 3 main groups others were responsible for the construction of rudders and centreboards, spinnaker bowsprit/prodder, 28m rotating wing mast complete with all Titanium custom fittings, boom, design and installation of onboard systems for which a detailed weight study was done. Although the displacement was only 8000 kg, the internal fit-out and systems were comprehensive comprising 2 refrigeration and 1 freezer unit, fully equipped galley and built in deck level bar-BQ, air conditioning and power generator to support the required comfort level during cruising passages. The simultaneous progress on all these fronts was made possible by the coordination effort of Trimarine’s offices in Italy and UK working in strict electronic contact with the office deployed in Brazil sharing the responsibility for the construction of the major elements and the overall assembly as well as materials and hardware components procurement. For the wing mast construction Trimarine developed a 34 m tunnel oven alongside the main Yard assembly area where another team was charged with the construction of mast male plugs, carbon fibre female symmetrical mould and HM carbon pre-preg mast shells including reinforcements, detail fittings and final assembly and paint finish.